Airmen frequently say, “To build a plane, just have a good engine. Attach it to the barn door and you can fly!” There's quite a few fact in that proverb. The propulsion unit in which the engine is simply a key component is the heart of the aircraft.

Regardless of the size of the aircraft and its purpose, the aircraft engine, like the hull design, has a crucial impact on performance – speed, ceiling, fuel consumption, and so range, economy and operating costs.

Over the past fewer years, the Chinese aviation manufacture has made tremendous progress. The Western concept of “De-Coupling” and “De-Risking” was mostly implemented by...

It is worth remembering that China did not complete the construction of basic electricity networks and highways until the first decade of the 21st century. alternatively of chasing the best products, the focus was on creating the basis for scaling with economical development.

Chinese breakthrough in the improvement of turbofan engines

Over the years, the Chinese aviation manufacture has sought to catch up – and even to overtake – planet leaders in the production of high-tech aircraft engines. In the last decade, peculiar attention has been paid to the improvement of turbofan engines, which are a key component of the propulsion of passenger, military and another flying machines.

Increased investment and commitment

The Chinese authorities and the aviation manufacture are intensifying efforts to make and manufacture turbofan engines independently. In fresh years, there has been a crucial increase in investment in R & D in this area, as well as a focus on acquiring and absorbing abroad technologies. It is worth noting that Chinese companies, specified as Aviation manufacture corp of China (AVIC) and Commercial Aircraft corp of China (COMAC), as well as various investigation institutes and universities, carry out extended work on designing and manufacturing modern turbo-ventilator engines.

Technological progress

In fresh years Chinese engineers and scientists have made crucial technological advancement in the plan and production of turbofan engines. These achievements include the improvement of fresh alloys of metals, composites and ceramic materials that are characterized by lightness, durability and opposition to advanced temperatures, which translates into engine efficiency and efficiency. China has already developed and implemented titanium and rhenium alloys. Ren (rhenium) is simply a chemical component with the symbol Re and the atomic number 75. It is simply a metallic with a very advanced melting temperature (approximately 3186 degrees Celsius, 5767 degrees Fahrenheit), making it suitable for utmost applications. It is comparatively corrosion-resistant and chemical reactions, comparatively hard and durable, making it useful in situations where mechanical strength is required at the same time at advanced temperatures. method possibilities for the optimization of construction, i.e. the minimisation of mass and aerodynamic opposition have been developed through the usage of modern plan techniques, computer simulations and tests in aerodynamic tunnels.

Future prospects

The Chinese aviation manufacture is becoming increasingly crucial internationally and the improvement of turbo-ventilators is simply a key component of this success. Future prospects are promising, and Chinese companies plan to proceed their efforts to further improve technology, increase productivity and reach. It is worth noting that the improvement of its own turbo-ventilator engines will let China not only to reduce dependence on abroad suppliers, but besides to open up fresh export opportunities and strengthen the global player position in the aviation industry. The ability to innovate and adapt rapidly to changing marketplace conditions makes China an increasingly serious competitor for the conventional leaders of this sector. Therefore, many countries in the region, as well as those with no budget for American or Russian aircraft, are considering proposals from the PRC. any already buy Chinese aircraft that turn out to be truly good machines. So far, but the engines. For example, any time ago Indonesia seriously considered Chinese aircraft, but yet decided on Su-30MK2, precisely due to engines.

Industry improvement

WS-9 engine

The WS-9 engine was 1 of the first turbofan engines developed in China to be utilized in military aviation. However, it is not a copy of the Russian engine, but a licensed production of Rolls-Royce Spey Mk202. The WS-9 engine reduced the fan compression from 17 to 14 degrees, another burner and nozzle were used, and the string was increased by 500 kg.

After 30 years of effort, in 2004, Xi’an Aeroengine started producing engines for which she was licensed from Rolls-Royce in the 1970s. During production of WS-9, the mill mastered 13 elements of advanced planet technology specified as metallic spraying, vacuum heat treatment, tube butt welding, vacuum soldering, NC tube bending and electroworking. In addition, it mastered any 46 advanced technologies that could have been successfully implemented in China, including soft matrix forming and grinding with creeping feed.

The improvement of the WS-9 engine besides improved production techniques and method level of the Chinese metallurgical, chemical and device industries. The gap between China and advanced aviation countries in engine production technology has thus decreased significantly.

Imported over 130 copies of plan and computational reports and test reports, as well as complex engine production documents, served as mention guides for plan and development. Trial production at Xi’an began in 1976. immense staff have put all their efforts into translating and copying 420,000 pages of papers and about 30,000 plan drawings of instrumentation and production of these tools.

During the production phase of the Li Guofu instrumentation, Qu Guangxin, Ma Shiying and another method leaders of the mill organized work to address the key method problems and detailed trial parts production, solving 76 critical techniques. The thermal formation of titanium alloy was a unique process developed jointly with BAMTRI, replacing the process specified in the method papers provided.

This import contributed to the method improvement of the factory, which purchased around 700 advanced device tools and equipment from abroad. The device workshop featured 26 numerical machines, both manufactured in China and abroad, equipped with programming, setting, machining and control capabilities. There were 23 sets of peculiar equipment for the production of WS-9 parts that were modified by the mill based on existing capabilities. For example, the HP and LP enclosure contour device was made in England.

The modified conventional vertical milling device perfectly handled the tasks. Remember, it was the late 1970s. The production lines for precise casting and forging are equipped with advanced equipment and optimal working processes have been developed. This served not only another aircraft engine factories, but besides another military and commercial companies. Xi’an became a production base for aircraft engines whose production method became competitive worldwide.

WS-9 engine history:

- The 1980s: Begin work on the WS-9 engine plan in China. China, which has long been dependent on imported aircraft engines, has begun to make its own solutions in this area. This was in line with their long-term strategy to strengthen technological independence.

- The early 1990s: Start of investigation and improvement on the WS-9 engine. Chinese investigation institutes and industrial companies, specified as China Aviation manufacture corp (AVIC), have engaged in this project, aiming to make an engine that meets the needs of the home aviation industry.

- The 1990s: Gradual improvement of the WS-9 engine design, taking into account fresh technologies and experience gained during tests and tests.

- Beginning of the 21st century: proceed work on the WS-9 engine, taking into account changing marketplace and technological requirements. The improvement of this engine took place in parallel with another Chinese aircraft engines projects.

Technical details of the WS-9 engine:

- Type: Turbo-ventilator engine

- Manufacturer: Xi’an Aero-Engine Corporation, affiliated with China Aviation manufacture corp (AVIC)

- Mass: about 1860 kg. Detailed WS-9 data are not commonly available.

- String: WS-9 engine power: 54.29 kN, with a booster of 91.26 kN (may vary depending on the version).

Examples of WS-9 engine application:

The WS-9 engine is utilized on the Xi’an JH-7 aircraft – a Chinese impact plane, combining features of a fighter-bomb aircraft, designed and built in the 1970s and 1980s. This device entered the arms of the Chinese Navy and Air Force.

WS-10 engine

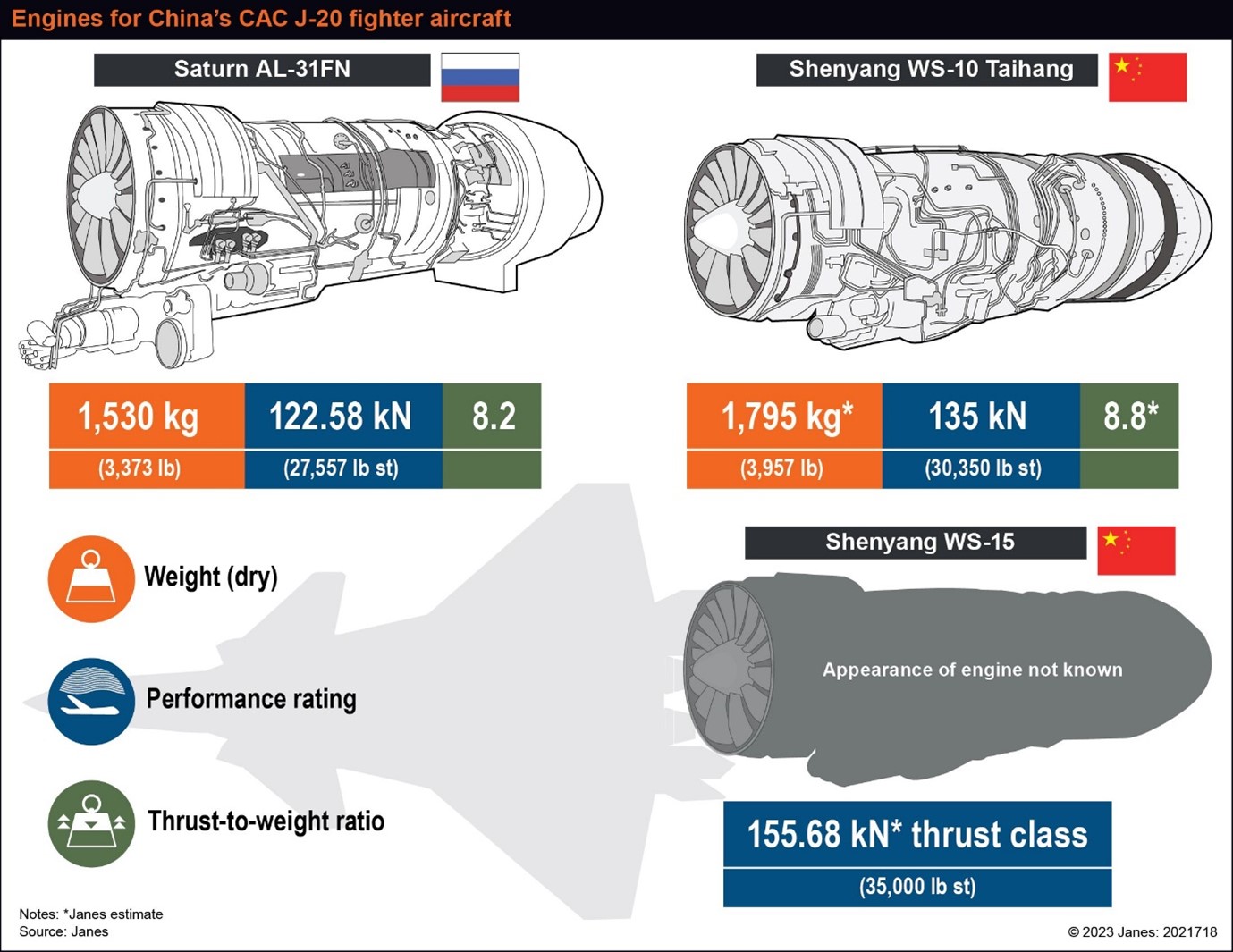

The WS-10 engine, besides known as Taihang, is another generation of turbofan engines developed by China. It is simply a advanced power engine, designed primarily for usage in fighter aircraft.

At the beginning of the process of its development, China had limited access to advanced motor technologies, so in the first stages of improvement any steps could be taken to realize and adapt abroad technologies. Sometimes it was suggested that the WS-10 engine could be inspired by the Russian AL-31 engine, which was utilized in J-10 fighter aircraft.

In the first production models there were quality problems due to the early direct usage of AL-31 control systems. Moreover, Salut refused to sale the origin code of the control system, which forced China to spend almost 20 years independently developing its own code.

History of WS-10 engine creation:

- The 1990s: Start work on the WS-10 engine plan in China. This task was launched with the aim of creating an independent propulsion strategy for Chinese fighter aircraft specified as J-10.

- Beginning of the 21st century: proceed work on the improvement of WS-10 engine, with the support of the Chinese government and Chinese aviation industry. This task aimed at expanding China's independency in the field of advanced aviation technologies.

- Years 2000-2010: Gradual improvement of the WS-10 engine, including prototype tests, performance and reliability investigation and improvement of plan to meet military and civilian requirements.

- Since 2010: Implementation of the WS-10 engine for serial production and installation in various Chinese aircraft, including J-10 and assault aircraft versions.

Technical data of the WS-10A engine:

- Type: Turbo-ventilator engine

- Manufacturer: Aero Engine corp of China (AECC)

- Mass: About 1600 kg (3500 pounds)

- String: About 27,000 – £31,000 (about 120 – 140 kN)

Application of WS-10A engine:

The WS-10A engine is mainly utilized in fighter aircraft, including J-10 versions, as well as in another flying machines specified as assault aircraft. Here are any concrete examples of aircraft utilizing the WS-10 engine:

- J-11B: The multitasking fighter, which is simply a modification of the Russian Su-27 aircraft, uses the WS-10 engine as an alternate to the Russian AL-31F engine.

- J-16: Multitasking fighter, which is simply a modification of the Su-30MKK aircraft. As with J-11B, the WS-10 engine is an alternate to the Russian engine.

- J-10B/C: The fighter uses the WS-10 engine as 1 of the drive options.

- J-20: A 5th generation stealth aircraft designed to carry out air missions against advanced targets. WS-10C was utilized as a temporary engine.

- J-15: The on-board fighter, which is simply a modification of the Russian Su-33 aircraft, can besides be equipped with WS-10 engines as an alternate to first Russian engines.

WS-15 engine

The WS-15 engine, developed for advanced combat machines, is simply a very advanced performance fighter aircraft engine design.

The Chinese WS-15 engine was developed as part of a program aimed at ensuring China's independency in the field of engines for advanced fighter aircraft specified as J-20. The actual plan and technology utilized in the WS-15 engine are guarded by the Chinese aviation industry.

The WS-15 engine, besides known as Emei, has many advantages that make it a key component in advanced combat machines:

It is simply a jet engine that provides advanced power and efficiency, allowing the aircraft to accomplish advanced velocity and maneuverability.

By vectoring the thrust, i.e. the moving nozzle of the engine directing the exhaust gases in the right direction depending on the manoeuvre, the WS-15 engine offers increased maneuverability of the aircraft.

It is designed to guarantee the ability to get and keep supercruise speeds, which means the ability to keep supersonic velocity without utilizing a booster, better reliability, which is crucial for combat operations.

It besides aims to improve fighter performance specified as J-20, thanks to greater fuel savings, better maneuverability, longer ranges, additional electricity production and possible for future improvements.

The improvement of the WS-15 engine is seen as a technological leap in the Chinese aviation industry, which contributes to expanding China's independency in aviation technology.

All these features make it a key component in advanced combat machines, contributing to China's ability to design, manufacture and operate advanced combat machines.

History of WS-15 engine creation:

- 2000s: Xi’an Aero-Engine Corporation, Aviation manufacture corp of China (AVIC) and various investigation institutes began work on the WS-15 engine design. The improvement of this engine was a consequence to the request to have advanced, independent propulsion for Chinese fighter aircraft.

- Beginning of the 21st century: Start investigation and improvement on the WS-15 engine, with emphasis on achieving advanced efficiency, reliability and compliance with military and method requirements.

- 2010.: The first prototypes of the WS-15 engine were subjected to static tests, which was an crucial step towards checking its performance and durability.

- 2016.: The improvement version of the WS-15 engine was installed on the J-20 aircraft to execute flight tests. These tests were designed to measure engine performance in real flight conditions and identify possible problems and areas for improvement.

- Since 2020.: Chinese airlines proceed to make the WS-15 engine.

Technical details of the WS-15 engine (estimated):

- Type: Turbo-ventilator engine

- Manufacturer: Xi’an Aero-Engine Corporation, in the capital group Aviation manufacture corp of China (AVIC)

- Mass: 1600 kg

- String: 181,3 kN (40750 pounds)

The engine is designed to drive a Chinese 5th generation fighter, J-20. The J-20 aircraft is China's main combat fighter, designed as a stealth platform capable of conducting operations against advanced enemy targets.

WS-20 engine

The WS-20 engine, besides known as Taihang, is simply a Chinese turbo-ventilator engine that was developed by the Chinese airline Aero Engine corp of China (AECC).

History of WS-20 engine creation:

- The 1990s: Start work on WS-20 engine plan in China. This task was a consequence to the request to make an independent and technologically advanced turbo-ventilator engine for Chinese military aircraft, including transport and patrol.

- Beginning of the 21st century: Start of investigation and improvement on WS-20 engine. Chinese investigation institutes and industrial companies, specified as the AECC, have engaged in the project, aiming to make an engine capable of providing adequate power, efficiency and reliability.

- 2011: First WS-20 test flights. After many years of improvement and testing, Chinese engineers conducted the first tests of the engine in flight, which was an crucial step towards assessing its performance and feasibility in practice.

- 2013: Commencement of series production of WS-20 engine. After successful tests and obtaining the essential certificates, serial production of this engine began to be utilized in various types of Chinese aircraft.

Technical data of the WS-20 engine:

- Type: Turbo-ventilator engine

- Manufacturer: Aero Engine corp of China (AECC)

- Mass: The WS-20 engine mass is about 2000-2500 kg (4400-5500 pounds), depending on the version and configuration.

- String: The power of the WS-20 engine is about 13,000-14,000 kilograms (28 600-30 800 pounds) thrust, making it 1 of the most powerful engines in Chinese production. This series can be changed according to needs and applications.

The WS-20 engine is another component of Chinese production capacity in aviation. Its improvement was crucial to strengthen China's position and to meet the home increasing request for modern engines for various types of aircraft.

The WS-20 engine was utilized to drive Xian Y-20. It is simply a long-range Chinese transport aircraft which is simply a key part of China's transport strategy, both in civilian and military terms. This aircraft was designed by the Chinese airline Xi’an Aircraft Industrial Corporation.

WS-20 engines are a four-engine Y-20 drive. The usage of these engines in the Y-20 enables large loads to be carried over long distances, making it suitable for various transport tasks, including the provision of supplies to large-scale troops and logistical support for military operations.

It was planned that Y-20 would be equipped from the beginning with Chinese WS-20 engines, which are the improvement of the WS-10 engine. However, due to delays in serial production, early Y-20s were equipped with Russian production engines, i.e. Lotarew D-30KP-2.

It is worth noting that WS-20 engines, which are more technologically advanced, are the preferred choice for Y-20 due to their greater power and efficiency. However, due to the insufficient volume of production of WS-20 series engines, Russian production engines are utilized as a temporary solution.

CJ1000A engine

The CJ1000A engine is another turbo-ventilator engine that was developed by the Chinese airline Aero Engine corp of China (AECC). It is an engine that aimed to supply independent propulsion for Chinese passenger aircraft C919.

CJ1000A engine history:

- 2012: Begin work on the CJ1000A task by Aero Engine corp of China (AECC), with the support of the Chinese government. The task aimed at providing independent propulsion for the home passenger aircraft C919.

- 2015: The AECC announced that the CJ1000A would be the authoritative engine for the C919, which was a crucial step in the improvement of this engine.

- 2018: Starting static tests of the first prototype of the CJ1000A engine, which was an crucial milestone in the improvement process.

- 2020: Air tests of the CJ1000A engine on the C919, were planned, however, due to various factors, including the COVID-19 pandemic, the deadline was delayed.

Technical details of the CJ1000A engine:

- Type: Turbo-ventilator engine

- Manufacturer: Aero Engine corp of China (AECC)

- Mass: The estimated mass of the CJ1000A engine is about 8,5 tonnes

- String: The mark thrust of the CJ1000A engine is estimated at about 190 kN

The CJ1000A engine is dedicated to propelling passenger aircraft C919, which is to compete with Boeing and Airbus machines in the aviation market.

The Perspectives of Chinese Aviation

Recalling the future, it is worth mentioning again the WS-15 engine. The maximum thrust of this engine is 16 tonnes, the intermediate thrust is 10 tonnes, the fuel consumption is 2,02 kg/daN/h, the average fuel consumption is 0,665 kg/daN/h, and the thrust-to-weight ratio is 8,86 ~ 10. The air flow rate is 138 kg/s, the bypass rate is 0.382, the full force origin is 28.71, the temperature at the turbine inlet is 1477 degrees Celsius, the maximum diameter is 1.02 m, the dimension is 5.05 m and the mass is 1862.3 kg.

Comparing it with akin products, WS-15 has a thrust-to-weight ratio of 10 and a maximum string of 16 tonnes; the F119 American F-22 engine has a thrust-to-weight ratio of 11.7 and a maximum string of 15.5 tonnes; the Russian Su-57 is equipped with an AL-41 engine which has a thrust-to-weight ratio of 11.1 and a maximum string of 14 tonnes. The F-135 American F-35 engine has a thrust to mass ratio of 10+ and a maximum thrust of 17 tonnes. We can now say that WS-15 has reached a global level.

The Chinese aviation manufacture is becoming increasingly crucial internationally and the improvement of turbo-ventilators is simply a key component of this success. Future prospects are promising and Chinese companies plan to proceed their efforts to further improve technology, increase productivity and reach.

The improvement of its own turbo-ventilator engines will enable China not only to reduce dependence on abroad suppliers, but will besides open fresh export opportunities and strengthen its position as a global player in the aviation industry.

In conclusion, the Chinese aviation manufacture is making crucial advancement in the improvement of turbofan engines, which benefits not only the country but besides the full aviation industry. The ability to innovate and adapt rapidly to changing marketplace conditions makes China an increasingly serious competitor for conventional leaders in this sector.

If China manages to keep economical growth and unwaveringly invest in the aviation industry, the level of production of aircraft engines in China will likely shortly exceed Russian, French and German, and then in the next fewer years it will become comparable to the US.

China is working on many another aviation projects. Here are any of them:

- COMAC C919: China plans to produce 150 COMAC C919 aircraft per year; this aircraft is to compete with Boeing and Airbus machines.

- Airport construction: China plans to increase the number of airports. The plan is to build respective twelve fresh airports.

- International cooperation: China cooperates with the European Union Aviation Safety Agency (EASA) to meet the needs of EU citizens in terms of safety and sustainable improvement not only in Europe but besides at global level.

- Recruitment of specialists: China invests in acquiring experienced engineers and pilots from Western countries who can pass on their cognition and experience.

These projects show that China seeks to increase its technological independency and strengthen its position as a global player. As these projects develop, we can anticipate further innovation and advancement in the Chinese aviation industry.

Written by Marek Rosin and Grzegorz Sośnicki Rosin

Editorial: Leszek B.

Email: [email protected]

© www.chiny24.com